(via TechCrunch)

In the last blog post I tried to give a sort of overview of the concept and the existing ideas around 3D-printing footwear. So in this post I want to address how I’m travelling with the project, and do a bit of a deeper dive into the research and literature surrounding the topic.

How is the project coming along?

When I first laid out my ideas for the project I think I too heavily leaned on the process of me attempting to make a 3D-printed shoe sole, while neglecting the more interesting things like the existing technology and its implications for the future of footwear.

For me, learning how this technology can be made viable for wider implementation is the most interesting part. I love all aspects of footwear, having worked in the industry at a retail and now corporate level. So I can definitely appreciate the effects that this technology will have on a grand scale.

My big question is about how we going to see it come to fruition commercially. Of course, as I spoke about in the last post there are major footwear brands starting to incorporate printing tech into their products. But what I want to know is how this will impact footwear going forward, are we going to see an era of mass personalisation?

Currently we are seeing these 3D-printed designs release in small numbers and higher price points. But as the industry continues to move with this tech we are no doubt going to see an increase in accessibility and decrease in cost for the average consumer.

However, I feel that this approach would be to the detriment of 3D-printing. Bringing its use in-line with existing manufacturing techniques feels gimmicky. Honestly, if you’re just going to substitute the foam midsoles that the market is familiar with to with 3D-printed versions that offer no added personalisation then I would think it’s safe to say it’s a waste.

What has already been published about it?

When I looked into what has already been published on this subject, I found my searches came up pretty bare. There seems to be very little published at an academic level. I think the reason for this is two-fold; the application of 3D-printing in the footwear/ textile industry is very new/ pretty experimental, and because it has been traditionally used in more ‘technical’ industries for prototyping/ construction.

However, articles outside of the scholarly space are plentiful. Due to footwear (more specifically sneakers) being part of the cultural zeitgeist, there are many publications writing about the latest styles and technological advances.

So what have I found?

- Anna Perry(2017) 3D-printed apparel and 3D-printer: exploring advantages, concerns, and purchases, International Journal of Fashion Design, Technology and Education, 11:1, 95-103, DOI: 1080/17543266.2017.1306118

This article examines the perceptions a group of study participants had to 3D-printed apparel and technology. The results indicated that the advantages (customisation and fit) were not the main drives to purchase, but the concerns (perceived comfortability and little ease of motion) were the dominant reasons for not buying.

- Corral, Laura C. and Walker, Kaitlyn J., “Exploring the Abilities of 3D Printing and its Viability for Consumption in the Fashion Industry” (2017). Apparel Merchandising and Product Development Undergraduate Honors Theses. 1. http://scholarworks.uark.edu/ampduht/1

This thesis first explores the process and applications of 3D-printing in a fashion context. The authors then explore the viability of 3D printed garments by making their own wear-test sample and measuring consumer response. The found overall perceptions to be positive, and concluded that further study and testing of its capabilities was warranted.

***I found that this paper really resonated with what I’m attempting to do but with textiles. They did the research and then tried to design and produce samples to further investigate.***

- AndresVH ‘Adidas Futurecraft 3D printed Sneaker’ Apr 2, 2017

https://www.thingiverse.com/thing:2221619

I found AndresVH’s CAD files on Thingiverse and it is definitely the best example of what I’m trying to replicate. He create a modular version of the ‘FutureCraft’ sole design, and although it isn’t to the same standard of printed using the same material, it is a very decent at home attempt.

(Above is the finished product combining the Adidas UltraBoost with the modular printed sole unit)

- Futurecraft by Adidas

This is what really put printed footwear technology on the map. Adidas had been on a roll with releases and were having their best financial period ever when they announced Futurecraft. It started out as a regularly 3D-printed sole unit, but once the German giants linked-up with the Silicon Valley based tech firm Carbon, Futurecraft 4D was born. Utilising Carbon’s Digital Light Synthesis technology, the 4D was dubbed the “world’s first high performance footwear midsoles crafted with light and oxygen,” designed to provide a controlled return of energy due to its lattice design.

If you have a few $$$ to blow you can purchase the Futurecraft 4D here and here.

As I spoke about in the last post, there has been a push in the last couple of years for the bigger brands to incorporate 3D-printing into their designs. While for a long time it was only prototypes being shown to the public, the last couple of years have seen commercially available models release from the likes of Adidas, New Balance, and Under Armour.

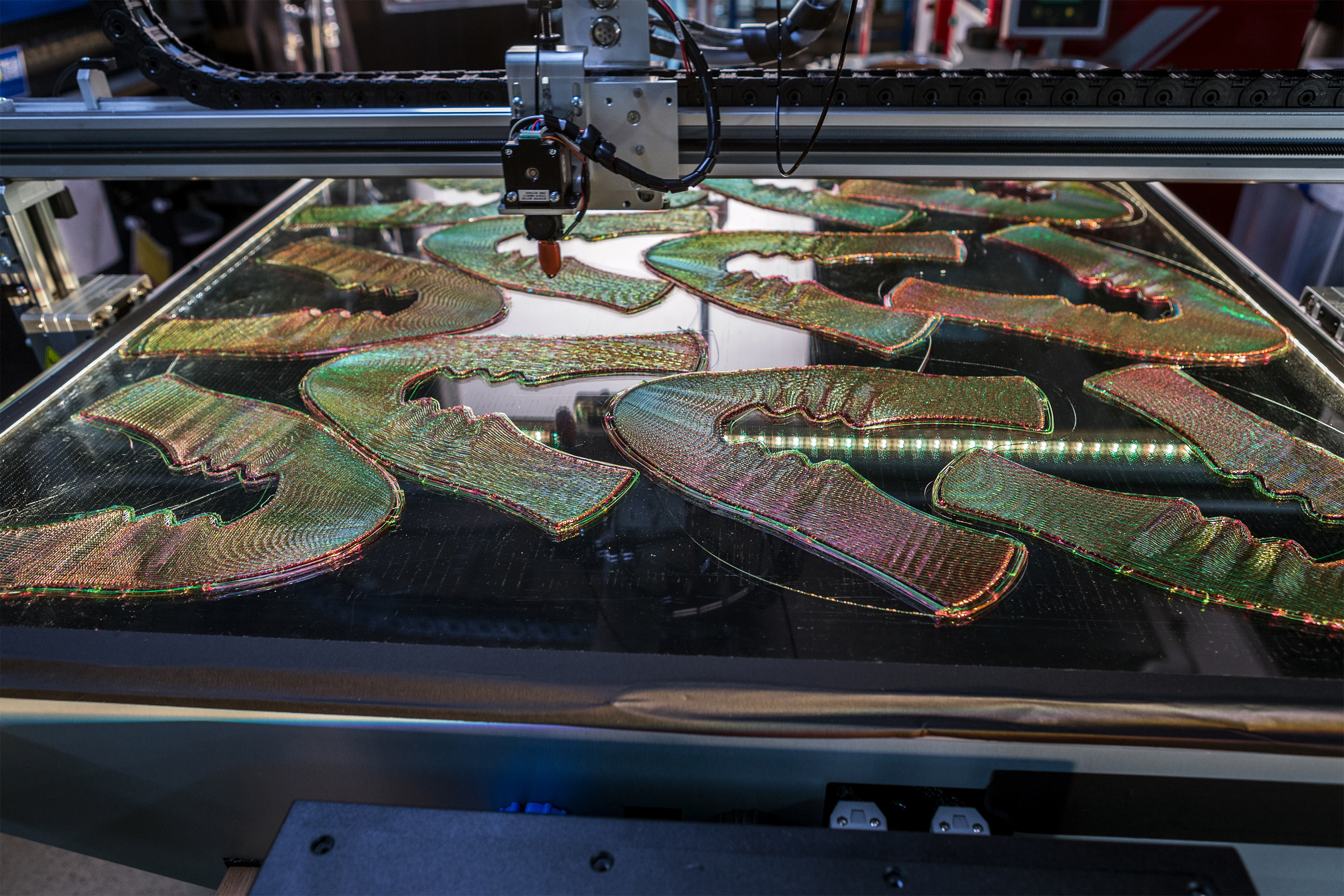

While the other big names in footwear have focused their efforts on printing soles. It’s only this week that Nike has announced their new Flyprint technology. Nike Flyprint is the first time we have seen a 3D-printed textile upper in the performance space. As a basic overview, Flyprint consists of a TPU filament that is unwound froma coil, melted and printed into specific layers. This printing method revolutionises the way in which performance footwear can be personalised. Flyprint starts with performance data collected from the athlete which is translated into the most beneficial Flyprint design. Nike have also engineered the process to bond with their existing Flyknit upper material, meaning enhanced flexibility and stretch in the design.

Thankfully, this breakthrough means I’ll soon be able to buy a pair of 3D-printed sneakers from my beloved Nike.

These are just a few examples of the information that’s out there about 3D-printing in the footwear industry. It’s fun to search through different 3D-printing CAD sites like Thingiverse to see some of the designs people have made. There’s also tonnes more information from the various footwear blogs, magazines and websites (here’s a good start).

As for my own 3D-printed creation I mentioned earlier progress has slowed. I haven’t found time to get a really good feel of how some of the CAD software like Blender work. One idea I have had however is to try and modify the design by AndresVH that I spoke about above. It gives me a basis to work up from rather than designing the lattice etc. from scratch.